Revealing the Intricacies of Next-Generation Power Units: a Deep Dive Into Advanced Engine Developments and layouts

In the world of vehicle engineering, the relentless pursuit of efficiency, performance, and sustainability has actually moved the development of power systems to unmatched elevations. As we stand on the precipice of a new era in transportation, the details of next-generation engine layouts beckon us to check out the cutting-edge technologies and developments that assure to redefine the driving experience. From sophisticated materials that push the borders of sturdiness and weight reduction to sophisticated turbocharging and turbo charging systems that raise power result to brand-new levels, each component of these power devices holds an essential to opening the future of vehicle engineering. Delving much deeper into the realms of discharge control, intelligent engine administration systems, and the perspective of power unit development, we discover ourselves on the cusp of a change that guarantees to improve the landscape of movement as we understand it.

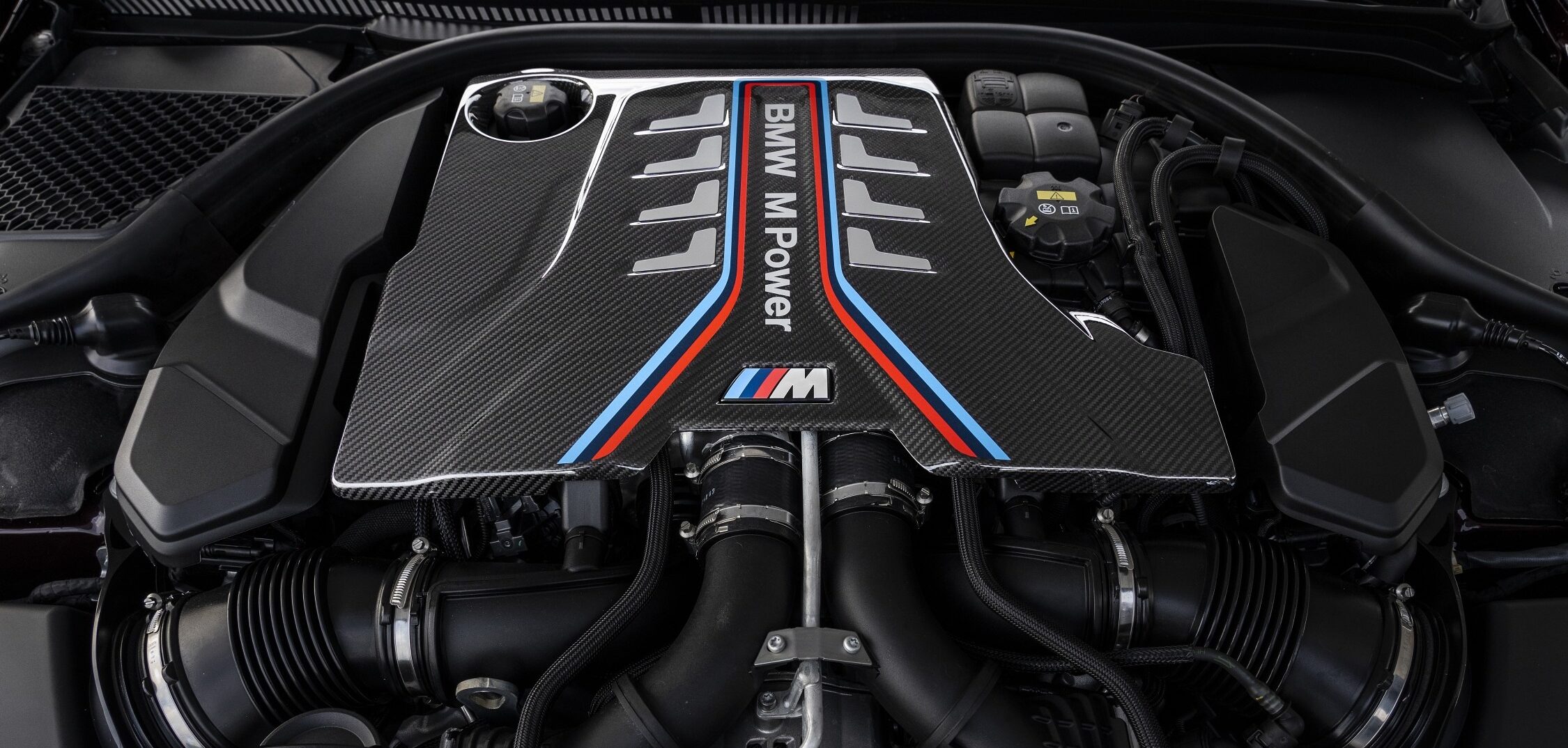

Advancement of Engine Materials

The change in the direction of advanced engine products has also allowed engineers to design engines with higher power outcomes while preserving gas effectiveness criteria. The use of lightweight materials lowers the overall weight of the engine, leading to improved gas economy and reduced discharges. Additionally, advancements in materials modern technology have enabled much better thermal monitoring within engines, leading to enhanced reliability and durability.

Turbocharging and Supercharging Technologies

How do Turbocharging and Supercharging Technologies transform engine efficiency and effectiveness in modern-day automobiles? Turbo charging and turbocharging are innovations that substantially improve engine efficiency by boosting the quantity of air consumption into the burning chamber. Turbocharging accomplishes this by making use of a generator driven by exhaust gases to pressurize the intake air, while turbo charging utilizes a belt- or chain-driven compressor to attain the same impact.

These technologies enable smaller sized, much more fuel-efficient engines to generate power comparable to bigger ones, recognized as downsizing. By forcing more air into the cylinders, turbocharging and supercharging improve combustion effectiveness, resulting in boosted horse power and torque result without a significant rise in engine size. This results in better acceleration, pulling capability, and total driving efficiency.

Additionally, turbocharging and supercharging add to boosted fuel efficiency by allowing the usage of smaller engines that consume less fuel under normal driving problems - bmw engine. This combination of enhanced efficiency and performance has made turbocharging and supercharging important elements of several contemporary engine designs

Discharge Control and Environmental Impact

With enhancing global worries regarding air high quality and ecological sustainability, the execution of emission control technologies in cars plays an important function in lowering harmful toxins released right into the ambience. link Modern lorries are outfitted with innovative emission control systems that aid minimize the environmental effect of automobile procedures. Catalytic converters, for example, are developed to transform harmful gases such as carbon monoxide gas, nitrogen oxides, and hydrocarbons right into less damaging substances like co2 and water vapor.

Additionally, innovations in engine technology, such as the integration of exhaust gas recirculation systems and discerning catalytic decrease, have actually substantially added to decreasing discharges. These technologies operate in tandem to enhance combustion efficiency and lessen the launch of unsafe toxins right into the air. Additionally, the development of hybrid and electric lorries represents a critical step in the direction of decreasing the overall environmental footprint of the transportation field.

Intelligent Engine Administration Systems

In addition, these systems allow vehicles to fulfill rigid exhausts criteria without jeopardizing efficiency, offering a much more eco-friendly driving experience. The assimilation of synthetic intelligence and machine learning capacities in engine monitoring systems remains to push the boundaries of what is visit site feasible, causing further enhancements in performance, integrity, and overall vehicle efficiency. bmw engine. As auto technology advances, intelligent engine monitoring systems will certainly play a critical function in forming the future of transport in the direction of a much more lasting and effective direction

Future Trends in Power Device Growth

As intelligent engine management systems lead the way for improved control and optimization in modern automobiles, future patterns in power unit development are positioned to redefine the landscape of auto propulsion innovations. Among the essential fads driving technology in power device advancement is the change in the direction of electrification. With a raising concentrate on sustainability and lowering carbon exhausts, hybrid and electrical powertrains are coming to be a lot more prevalent in the automobile industry. These alternate power resources use enhanced performance and performance while straightening with rigid ecological guidelines.

An additional substantial fad is the assimilation of advanced products and producing strategies. Light-weight products such as carbon fiber and light weight aluminum are being made use of to decrease total vehicle weight, improving gas performance and performance. Furthermore, advancements in 3D printing and additive manufacturing are enabling the manufacturing of intricate engine components with higher precision and resilience.

Additionally, expert system and machine discovering are playing an important duty in optimizing power device performance. These modern technologies permit real-time surveillance and flexible control, bring about much more efficient and reliable power distribution. Overall, future fads in power unit development are geared in the direction of performance, sustainability, and performance, driving the auto industry in the direction of a new era of propulsion modern technologies.

Final Thought

To conclude, the improvements in engine products, turbocharging, exhaust control, and intelligent management systems have led the way for next-generation power units. These developments have not only better performance and efficiency but also reduced environmental effect. As technology continues to progress, future fads in power device advancement are likely to concentrate on additional enhancing sustainability and maximizing power result. The complex layouts and innovations in modern engines showcase the continuous evolution of auto technology.

Discovering the dynamic innovations in engine materials has been pivotal in enhancing the performance and efficiency of modern-day engines. Over the years, the development of engine materials has played a vital role in pressing the boundaries of what engines can achieve.The shift towards progressed engine materials has actually additionally enabled designers to develop engines with greater power outcomes while keeping gas efficiency standards.The execution of smart engine administration systems in contemporary cars has transformed the way read review engines are managed and optimized for efficiency and performance. By accumulating data in real-time and assessing it with innovative algorithms, smart engine monitoring systems can adjust to driving designs, ecological aspects, and engine wellness to make best use of power outcome while minimizing fuel usage and emissions.